- Corporate Information and Management

- 2025.02.21

Received the Ultrasonic Symposium Best Paper Award at USE2023

February 21, 2025

Company:Nippon Paint Holdings Co., Ltd.

Representative:Yuichiro Wakatsuki

Director, Representative Executive Officer & Co-President

Wee Siew Kim

Director, Representative Executive Officer & Co-President

Contact:Ryosuke Tanaka

Executive General Manager

Investor Relations, Sustainability and Public Relations

(TEL +81-50-3131-7416)

Received the Ultrasonic Symposium Best Paper Award at USE2023

- Presenting a New Theory for Measuring Droplets on Substrates -

Nippon Paint Holdings Co., Ltd. is delighted to announce that, through joint research with a team led by Professor Keiji Sakai from the Graduate School of Engineering at The University of Tokyo, a new theoretical framework has been established for measuring the physical properties of droplets on substrates. This breakthrough was honored with the Best Paper Award at USE2023*1 (The 44th Symposium on Ultrasonic Electronics).

This research is part of a collaborative initiative under the Industry-Academia Collaboration Agreement signed on May 18, 2020.

Award Details

| Award Name | USE2023 Best Paper Award |

|---|---|

| Paper Title | Experimental and theoretical research on oscillation behavior of droplets on horizontally oscillating substrates |

| Authors | Satoshi Ishida (Nippon Paint Corporate Solutions), Shujiro Mitani (The University of Tokyo), Keiji Sakai (The University of Tokyo) |

| Key Highlights | This research establishes a new theoretical framework for measuring the physical properties of droplets applied to substrates. The breakthrough enables precise measurement of time-dependent changes in droplet properties, overcoming limitations of conventional methods. |

※1 USE Best Paper Award: The USE2023 Best Paper Award is given to individual researchers or research groups who have presented outstanding papers at the 44th Symposium on Ultrasonic Electronics. This award recognizes research contributions that are expected to drive significant advancements in ultrasonic science and technology. Recipients are chosen through a rigorous evaluation process conducted by the symposium’s Steering Committee, based on predefined selection criteria.

Key Points of the Paper

Research Background

Spray coating is a widely used technique for applying paint, where droplets with a diameter of tens of micrometers are sprayed onto a substrate and dry to form a coating layer. The application process and final coating appearance can be optimized by controlling key properties such as paint viscosity and surface tension. However, no method had been developed for measuring the physical properties of droplets after application. This limitation meant that paint development was conducted without a clear understanding of critical changes affecting coating quality.

This study marks a foundational step toward innovative paint development by establishing a theoretical framework for measuring the physical properties of droplets on substrates and designing a specialized measurement device.

Research Details

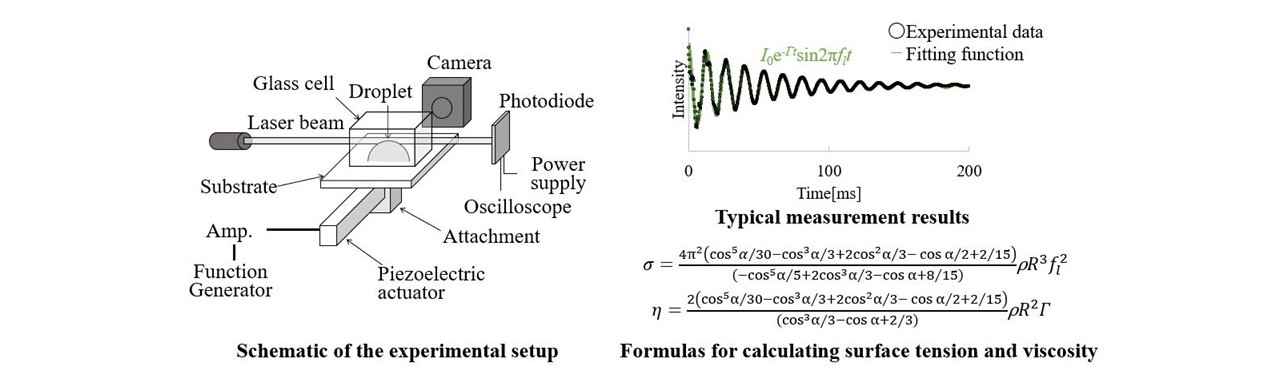

This study successfully established a new theoretical framework for measuring the physical properties of droplets on substrates and led to the development of specialized measurement devices. In our research, we induced shear deformation in a droplet by horizontally oscillating a substrate. The surface vector of the droplet was represented in a polar coordinate system, and its surface area was calculated using differential geometry. Furthermore, by analyzing the kinetic energy of the flow and solving the Lagrange equation, we derived the relationship between the droplet’s oscillation frequency and its surface tension. Additionally, we demonstrated that when the oscillation frequency is significantly higher than the damping constant, the energy of the droplet is proportional to the square of the amplitude. We also established the relationship between the damping constant and viscosity, showing that the rate of energy dissipation per unit time is proportional to both the viscosity and the square of the shear rate. Furthermore, since no existing device could measure the horizontal oscillatory behavior of droplets as derived in this study, we developed specialized measurement equipment. By utilizing the knife-edge method to detect droplet oscillation displacement, we achieved high temporal resolution. The device enabled displacement measurements at approximately 10,000 times per second, allowing for real-time tracking of oscillatory behavior in the range of several hundred Hz. Furthermore, it can accommodate even higher oscillation frequencies.

Using the newly developed device, we confirmed that the theoretical values derived in this study closely aligned with experimental measurements for liquids with various physical properties, thereby validating the proposed theory. Additionally, we conducted extensive experiments, including measurements of time-dependent changes in surface tension caused by solvent evaporation. In summary, this study produced a range of significant research outcomes, including the establishment of a theoretical framework for measuring the physical properties of droplets on substrates, the development of specialized measurement devices, and the successful validation of the theory through experimental analysis.

Future Prospects

The industrial applications of droplet-based coating and ejection extend beyond the paint industry, encompassing technologies such as inkjet printing and medical applications, including the delivery of drugs in microdroplet form to cells. The droplet horizontal oscillation method on substrates developed in this study has broad potential applications beyond paint manufacturing. Looking ahead, we will continue refining the device to enable the measurement of the physical properties of an even wider range of droplets.

For Reference

About the Social Collaboration Program

This research was conducted as part of the Social Collaboration Program titled "Creation of Innovative Coating Technologies." The program is a key initiative under the Industry-Academia Collaboration Agreement between The University of Tokyo and Nippon Paint Holdings Co., Ltd. Established to drive advancements in coating technologies, the Social Collaboration Programs spans a five-year period, running from October 1, 2020, to September 30, 2025.Related press releases

- “Nippon Paint Jointly Develops a High-Throughput Screening System for New Antiviral Materials”(April 28, 2022)(Available in Japanese only)

- “The University of Tokyo, Daikin Industries, and Nippon Paint Jointly Develop Reference Guides for Education Professionals to Reduce the Risk of Respiratory Tract Infections” (October 12, 2021)(Available in Japanese only)

- “Nippon Paint Group’s Five ProtectOn Brand Products Proven Effective in Surpassing the Novel Coronavirus (SARS-CoV-2) and Alpha Variant Through Joint Research with The University of Tokyo” (July 15, 2021)

- “The University of Tokyo and Nippon Paint Holdings Launch Japan’s First Social Collaboration Program Specialized in Paint” (November 24, 2020)

- Contact

- Nippon Paint Holdings Co., Ltd. Public Relations

- E-mail: nphd-kouho@nipponpaint.jp

- TEL: +81-50-3131-7416