- Research and Development

- 2025.03.03

Nippon Paint Jointly Develops Next-Generation In-Mold Coating Technology - Advancing Carbon Neutrality in Automotive Coating Processes -

March 3, 2025

Nippon Paint Automotive Coatings Co., Ltd.

Nippon Paint Jointly Develops Next-Generation In-Mold Coating Technology

- Advancing Carbon Neutrality in Automotive Coating Processes -

Uchihamakasei Corp. (Head Office: Toyota City, Aichi; President and Director: Eiji Kojima; hereinafter “Uchihamakasei”) and Nippon Paint Automotive Coatings Co., Ltd. (Head Office: Hirakata City, Osaka; President and Representative Director: Satoshi Nishimura; hereinafter “NPAC”) proudly announce the successful joint development of Japan’s first in-mold coating technology (IMC) for large thermoplastic automotive exterior applications.

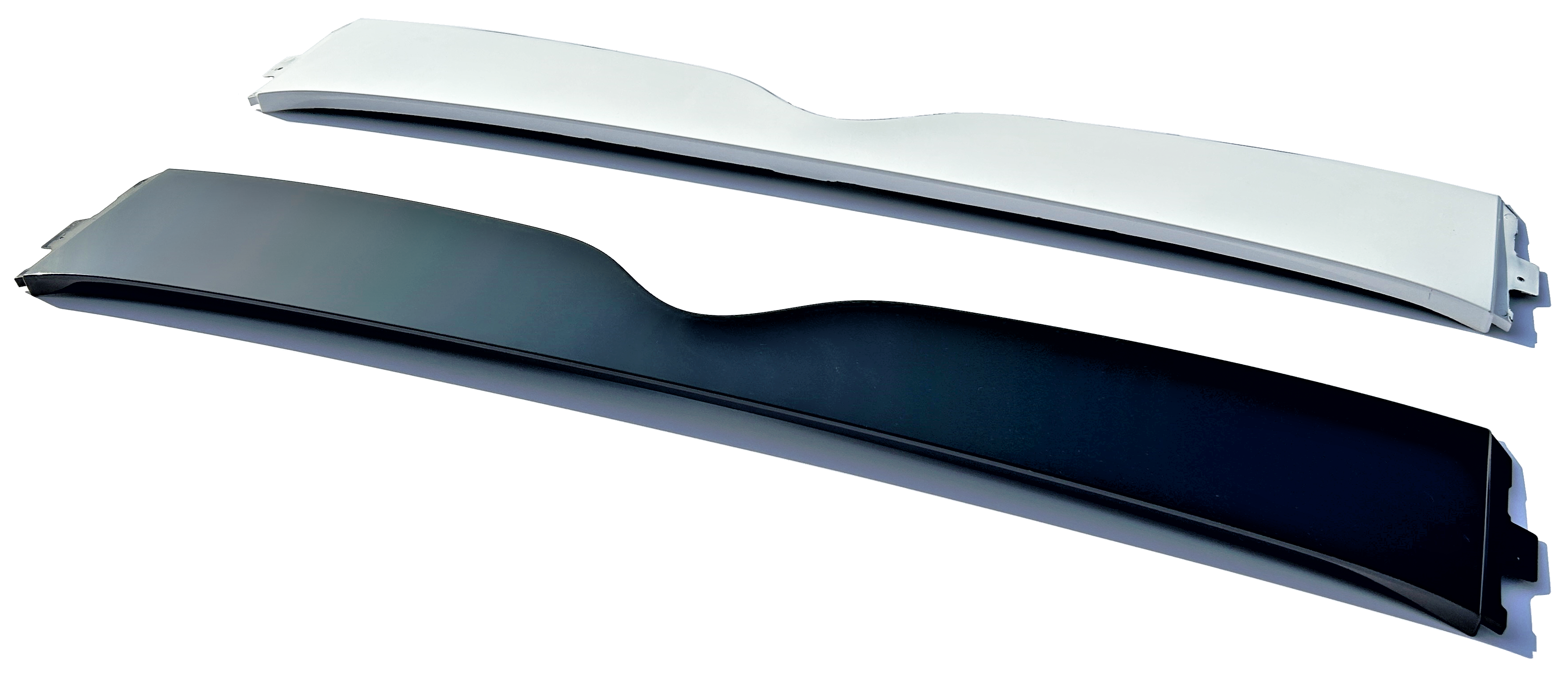

In-Mold Coating Prototype: Roof-Top Garnish (H 160mm x W 1020mm)

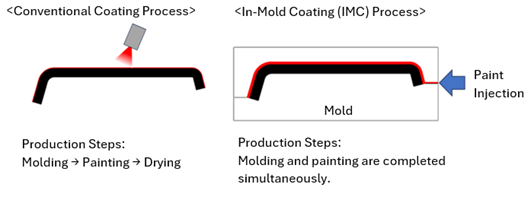

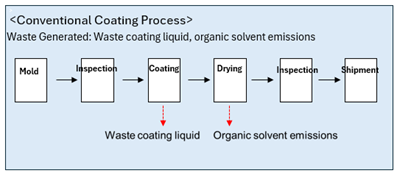

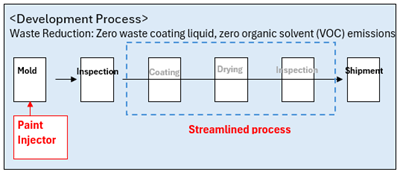

This innovative technology combines resin molding and surface coating into a single integrated process. After the resin is molded within the mold, paint is injected, forming a uniform coating film on the surface of the molded component. By eliminating the need for traditional coating application booths and post-coating drying ovens, this process significantly streamlines production, reduces CO₂ emissions by 60% (as estimated by Uchihamakasei), and contributes to achieving zero VOC emissions.

The in-mold coating technology utilizes solvent-free paint, developed by NPAC. These advanced coatings achieve a VOC emission reduction of 99% or more, significantly enhancing environmental sustainability. Furthermore, they maintain the same high-quality standards as conventional coatings.

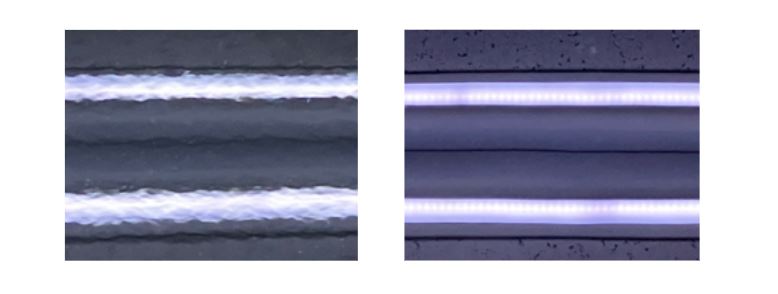

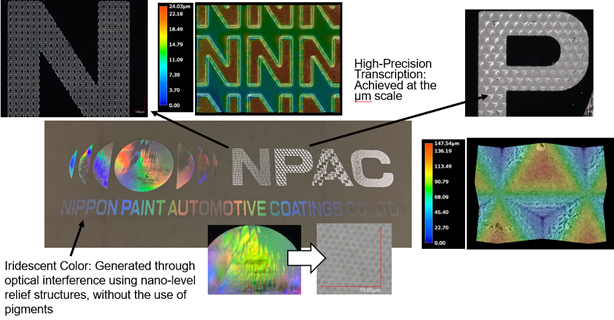

In the in-mold coating technology, Coating surface is formed through mold transcription,, achieving greater surface smoothness compared to general spray coating. Additionally, the high design reproducibility enabled by mold transcription reduces the occurrence of exterior flaws, contributing to improved productivity. Furthermore, in-mold coating makes it possible to precisely deliver designs, such as geometric patterns and embossed finishes, that cannot be achieved with spray coating. This technology also faithfully transcribes nano-level fine textures, enabling complex designs that were previously difficult to achieve with conventional spray coating, such as iridescent color created through structural color formation. These advancements open up new possibilities for automotive design.

To realize this technology, we optimized the properties of resins and catalysts while refining the coatings in collaboration with the in-mold coating process. As a result, we have developed an innovative technology that combines high-precision design expression with efficient manufacturing processes.

Moving forward, we aim to provide this new technology to automobile manufacturers with the goal of adoption in mass-produced vehicles.

◆About In-Mold Coating

- Background of Development

As the automotive industry strives to meet the Sustainable Development Goals (SDGs), there is increasing pressure to reduce environmental impact across all manufacturing processes, including coating technologies. In response to this demand, Uchihamakasei and NPAC have been actively engaged in the development of innovative, environmentally friendly coating methods, continuously taking on new challenges to achieve this objective.

It took several years of trial and error to develop processes that not only improve coating performance but also maximize productivity, making mass production possible. However, we have successfully established processes capable of supporting the mass production of in-mold coating for large thermoplastic automotive exterior applications.

- Characteristics

(1) In-Mold Coating Technology

Uchihamakasei’s in-mold coating (IMC) technology applies paint by injecting it directly into the injection mold, forming a uniform coating film on the surface of the molded component.

Unlike conventional spray coating methods, which achieve a coating efficiency of approximately 70%, the IMC process ensures 100% efficiency by directly integrating the paint into the molding process.

Additionally, traditional coating methods require large-scale drying ovens and approximately one hour of drying time. In contrast, IMC technology eliminates the need for drying ovens, as the coating process is completed entirely within the mold. By reducing the curing time of the coating to less than one minute, this technology significantly shortens the overall molding process while contributing to a substantial reduction in CO₂ emissions.

(2) Coating Technology

NPAC has developed advanced solvent-free paint for in-mold coating (IMC), minimizing VOC content to less than 4 grams per liter. These coatings are also expected to reduce CO₂ emissions by approximately 60%, contributing to a healthier working environment and a reduced environmental footprint.

Drawing on NPAC’s extensive experience in automotive coatings, these formulations deliver performance equal to or superior to conventional spray coatings. They ensure long-term durability by preserving both aesthetic quality and functional integrity, even under harsh environmental conditions.

<In-Mold Coating Process>

<Comparison of Processes with Conventional Coating>

<Comparison of Exterior Appearance Quality Under Fluorescent Lighting>

Left: Spray Coating, Right: In-Mold Coating

<Various Design Transcriptions Using Specialized Molds>

The Term “NPAC” Represented Through Various Design Techniques

N: with the letter “N” composed of numerous smaller “N” at a scale of several tens of micrometers

PAC: Formed with geometric patterns and embossed designs

Reference Video: In-Mold Coating—Iridescent Color Sample of Coating Film

Moving forward, Uchihamakasei and NPAC will continue to promote the adoption of this technology, striving to further minimize the environmental impact of automotive manufacturing processes